False Bottom Definition and Core Structural Functionality

What Is a False Bottom? Clarifying the Structural Concept

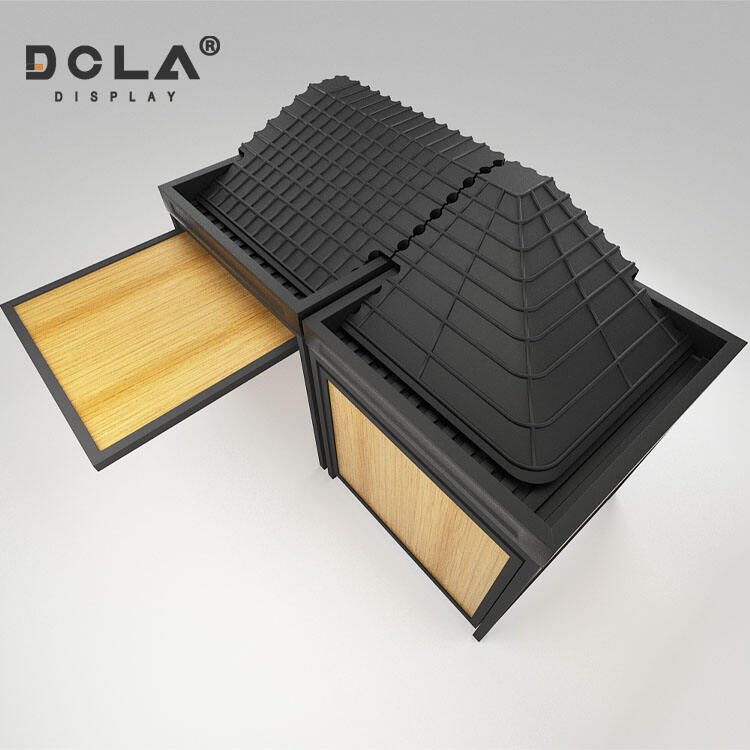

False bottoms are basically extra shelves placed just above the main base of display units. They create secret storage areas underneath while still looking like regular shelves from the outside. What makes them work so well is how they spread out the weight across the sides of the display instead of putting everything in the middle. Compared to solid bases, these false floors actually save materials because they have empty spaces built right in. Some estimates suggest material savings can reach around 30%, which is pretty impressive for such a simple design change. The main reason people install them though has more to do with looks than anything else. By raising items higher up towards where eyes naturally look, products stand out more without changing how big the display appears overall. Think of it kind of like those buildings where the heavy parts are hidden inside so we don't see them but they still hold everything together nicely.

How False Bottoms Optimize Shelf Density and Visual Impact in Retail Environments

Many stores have started using false bottoms as a clever way to pack more products without taking up extra space on shelves. When merchandise is lifted about 3 to 5 inches off the ground, retailers can stack items vertically which means getting around 15 to maybe even 20 percent more SKUs in the same area. This raised section tends to highlight higher priced goods while hiding all those brackets and supports underneath. It works especially well with shelf ready packaging systems because when staff need to restock quickly, everything looks neat and organized instead of cluttered with hardware. Plus there's this bonus feature too: the empty space beneath lets them attach security devices or sensors without anyone noticing. Clean looking displays actually matter quite a bit according to some shopping studies we've seen recently showing that customers are about 12 percent more likely to buy something when they don't see messy equipment hanging around.

Critical Safety and Compliance Limitations: Why False Bottoms Are Restricted in Pallet Displays

Structural Integrity Risks: Load Distribution, Compression Failure, and Worker Safety

When false bottoms are used in pallet displays, they actually weaken the overall structural integrity because they mess with how weight gets distributed evenly across the base. What happens is there's this hidden empty space underneath that cuts down on compression resistance. Studies looking at material stress have found that failure rates can jump as much as 40% when these pallets get stacked or moved around during transport operations. Instead of spreading pressure across central support beams, the weight ends up concentrating on the edges, making it much more likely for whole sections to collapse suddenly when being handled or stacked improperly. Forklift accidents make matters worse since they create extra shear forces through already weakened load paths. Warehouse workers face serious safety risks from these failures too. Stock falls off, pallets break apart completely sometimes. According to data from the National Safety Council released last year, such incidents rank among top causes of injuries in logistics environments. Given all these problems, false bottom designs just don't work well in industrial settings where proper weight distribution across the entire base area remains a basic requirement for safe operations.

Regulatory Enforcement: False Bottom Prohibitions in Major Retailer Requirements

Big box stores have strict rules against using false bottoms in their pallet displays as part of broader safety measures across the supply chain. Warehouse giants insist that products must sit flat on pallet surfaces with no hidden gaps between layers. Why? Because there have been real problems. According to research from Ponemon Institute back in 2023, broken false bottoms alone were responsible for more than $740k worth of damaged goods each year. Retailers check compliance through several important verification points including:

- Pre-shipment load testing to confirm even weight distribution

- Compression resistance thresholds exceeding 2,500 lbs

- Third-party certification of structural blueprints

Violations trigger immediate shipment rejection, financial penalties, and—for repeat offenders—loss of shelf space. This strict enforcement reflects broad alignment with OSHA’s load stability guidelines, cementing false bottoms as non-compliant by design in pallet-based retail logistics.

False Bottom vs. Butterfly Skirt: Key Design, Function, and Application Differences

Mechanical Comparison: Support Geometry, Weight Transfer, and Assembly Flexibility

The way false bottoms and butterfly skirts handle weight distribution is pretty different between these display systems. With false bottoms, we're talking about those setups that need vertical supports like plastic legs or wooden blocks to hold up the platform. The problem here is that all the weight gets focused on just a few small spots where the supports touch the ground. Retailers have noticed this makes their displays less stable overall. Some studies actually show displays with these concentrated supports fail about 30% more often in busy stores compared to other options. Butterfly skirts work differently though. They use those angled corrugated flaps that spread out when deployed, creating a much wider base area. This spreads the weight across the whole surface rather than concentrating it. We've seen this design cut down point-load stress by around 70%, which means they handle uneven floors better too. When it comes to putting them together, there's another big difference. False bottoms can be a pain because everything needs to line up perfectly and sometimes extra bracing is needed. Butterfly skirts? Most people can set them up in just seconds thanks to those built-in folds. No tools required! This makes them great for last-minute store promotions where getting something assembled quickly and safely matters most.

Strategic, Compliant Applications: Where False Bottoms Enhance Presentation Without Compromising Safety

Shelf-Ready Packaging (SRP) and End-Cap Displays: Controlled Use Cases for Brand Visibility

False bottoms are permissible—and effective—in low-risk, shelf-based applications like Shelf-Ready Packaging (SRP) and end-cap displays. Designed for direct shelf placement, SRP units impose lighter loads (typically under 50 lbs), allowing false bottoms to operate safely within engineered weight limits. Retailers approve this controlled use because it:

- Eliminates compression concerns through tightly constrained footprint dimensions

- Maintains structural integrity using reinforced corrugated supports

- Aligns with vertical merchandising standards for shelf-level displays

Here, the false bottom shifts focus from load-bearing to presentation—elevating products to prime eye-level positions and enabling tiered visual storytelling. When applied this way, it strengthens brand visibility by up to 30% in high-traffic zones without violating warehouse safety protocols or shopper-facing compliance requirements.

Frequently Asked Questions

What is the primary benefit of using a false bottom in retail displays?

False bottoms primarily enhance the visual appeal of products by elevating them to eye-level positions, thereby increasing product visibility without needing to alter the overall size of the display.

Why are false bottoms not suitable for pallet displays?

False bottoms can compromise the structural integrity of pallet displays by interfering with weight distribution. This can lead to increased failure rates and pose significant safety hazards in industrial environments.

Can false bottoms be used in all retail settings?

False bottoms are ideally used in low-risk shelf-based applications, such as shelf-ready packaging and end-cap displays. They are not recommended for pallet-based logistics due to regulatory and safety concerns.

Table of Contents

- False Bottom Definition and Core Structural Functionality

- Critical Safety and Compliance Limitations: Why False Bottoms Are Restricted in Pallet Displays

- False Bottom vs. Butterfly Skirt: Key Design, Function, and Application Differences

- Strategic, Compliant Applications: Where False Bottoms Enhance Presentation Without Compromising Safety

- Frequently Asked Questions